Dear Catalysis Researchers,

Welcome to our monthly newsletter Magic Powder dedicated to the catalysis research and development.

In this monthly issue,

First of all, we will introduce our member Assoc. Prof. Dr. Bahar İpek Torun who was awarded with 2024 The Young Scientist Award Program of the Science Academy (2024 BAGEP) (Page 2). The Young Scientist Award Program of the Science Academy, funded by donations from individuals and institutions since 2013, provides cash research support for a period of two years to scientists under the age of 40. The aim of BAGEP is to reward and encourage the brightest and most promising young academics with a prestigious scholarship that will assist them in their research. In the selection of award recipients, the candidates' backgrounds, planned research, potential as researchers, and future plans are taken into consideration.

Secondly, we will introduce the research laboratory of one of our founding member, Prof. Dr. Emrah ÖZENSOY in Bilkent University, Chemistry Department (Page 3).

-Thirdly, as a continuation of an article about AI and machine learning, Prof. Dr. N. Alper TAPAN will present a case study of machine learning on direct alcohol fuel cells (Page 7).

And finally, again as a tradition, you can see short summaries of most recent high impact research articles conducted by Turkish Catalysis Community (Page 13).

And thanks a lot for being part of our catalysis community. We look forward to bringing you more exciting updates in the next edition of our newsletter. We are always open to contributions of academic and industrial partners in our upcoming issues.

As usual, Professor Merlin Catalystorius has always something to say although he is on vacation 😊.

Editorial Board:

Prof. Dr. Ayşe Nilgün AKIN

Prof. Dr. N. Alper TAPAN

Dr. Merve Doğan Özcan

Contact info:

Email:katalizdernegi@gmail.com

Linkedin: https://www.linkedin.com/in/kataliz-derneği-272879a

Awards In Our Community

Associate Professor Bahar İpek Torun has been awarded the 2024 BAGEP award in the field of Chemical Engineering. Associate Professor Bahar İpek Torun graduated from the Department of Food Engineering at METU and the Minor Program in Chemical Reaction Engineering at the Department of Chemical Engineering at METU in 2008. Between 2008 and 2011, she conducted her Master's studies in the Department of Chemical Engineering at METU under the supervision of Prof. Dr. Deniz Üner, with a thesis titled "Photocatalytic Carbon Dioxide Conversion in Liquid Medium." From her Master's studies, she published a book chapter titled "Artificial Photosynthesis from a Chemical Engineering Perspective" with Prof. Dr. Deniz Üner. Between 2011 and 2016, she conducted her Ph.D. studies in the Department of Chemical and Biomolecular Engineering at the University of Delaware under the supervision of Prof. Dr. Raul F. Lobo. During her Ph.D., she gained experience in synthesis, atomic-level characterization, and catalytic or adsorption applications in topics such as "Direct Methanol Production from Methane with Copper-containing Zeolites," "Hydrogen Storage with Zeolites," and "Organic-Inorganic Hybrid Perovskites," publishing 5 articles and 9 conference papers.

After completing her Ph.D., Bahar İpek Torun began her academic career as an Assistant Professor in the Department of Chemical Engineering at METU in 2017 and was promoted to Associate Professor in 2023. By 2024, she had published 17 international articles, 2 book chapters, 24 conference oral presentations, and 22 poster presentations. Between 2017 and 2024, she led two ARDEB 1001 projects, one ARDEB 3501 project, one ARDEB 2232 project, and five METU BAP projects. She also served as a researcher in one ARDEB 1001 project, one TEYDEB 1507 project, one TEYDEB 1505 project, and as a consultant in one ARDEB 1001 project. She continues her research in the Department of Chemical Engineering at METU with catalytic studies on Direct Methanol Production from Methane and Methanol or Methane Production via Carbon Dioxide Hydrogenation.

Ozensoy Research Group: Catalysis for Energy, Environment, and Sustainability

Ozensoy research group at Bilkent University Chemistry Department in Ankara (https://ozensoylab.bilkent.edu.tr/) endeavors to specialize in the design and synthesis of novel heterogeneous catalysts, elucidating their functionality across diverse applications including alternative energy, sustainability, environmental stewardship, and aerospace industries.

The group boasts a robust infrastructure facilitating:

i) Synthesis of sophisticated catalytic nanostructures,

ii) Elucidation of intricate heterogeneous catalytic mechanisms,

iii) Deployment of in-situ spectroscopy for precise characterization,

iv) Profound insights into catalytic interface structures at the molecular scale,

v) Revelation of novel structure-function correlations.

Our comprehensive research spans physical chemistry, chemical physics, chemical engineering, material science, and nanotechnology, encompassing groundbreaking investigations such as:

i) Development of original catalytic nano-materials for high-purity hydrogen production from biomass by-products,

ii) Photocatalytic remediation of air pollution using solar energy,

iii) Transformation of bio-ethanol into high-value chemicals through catalysis,

iv) Advancement of automobile catalytic converter technologies,

v) Integration of catalytic decomposition of ionic liquids into aircraft propulsion systems.

vi) CO2 reduction and valorization to valuable products

vii) Chemical energy storage and conversion via catalysis

Critical to addressing contemporary technological challenges, our group delves into the surface chemistry of catalytic materials, exploring complex systems including mono-metallic/multi-metallic nanoparticles, mesoporous metal oxides, perovskites, and zeolites. Characterization techniques such as in-situ FTIR, ATR-IR, XRD, BET, Raman, TEM, SEM, EDX, EELS, ICP-MS, and XPS are employed. Furthermore, catalytic reaction mechanisms are scrutinized via planar single-crystal/thin film model catalysts at the molecular level, employing IRAS, TPD, LEED, XPS, and UHV techniques. These endeavors are complemented by theoretical simulations using DFT calculations through collaborative efforts. Advanced operando measurements, including XANES and EXAFS, conducted at international Synchrotron facilities, further enrich our understanding of catalytic nano-materials.

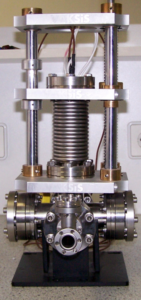

Instrumentation & Infrastructure

UHV

Model catalysts (single crystals and ultra-thin films) analysis via IRAS, XPS, TPD, and LEED.

In-situ FTIR and TPD

Real-time investigation of surface reactions on mesoporous powder catalysts by combining vibrational and mass spectroscopy.

XPS

SPECS Phobios XPS system for surface analysis of nano-materials, thin films, and powders.

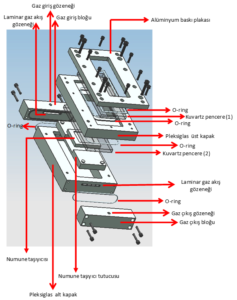

Catalytic Flow Reactor

Custom-made flow-mode reactor with, QMS, and Chemiluminescent NOx Analyzer.

Photocatalytic Performance Test System

Gas phase photocatalytic activity & selectivity investigation in flow mode in a custom-made reactor using Chemiluminescence NOx Analyzer.

Thus, Ozensoy group’s multifaceted approach aims to integrate cutting-edge synthesis, advanced characterization, and theoretical insights to drive innovations in catalysis, thereby aspiring to contribute significantly to scientific and technological advancement (https://ozensoylab.bilkent.edu.tr/publications/).

A Case Study of Machine Learning Approach: Direct Alcohol Fuel Cells - Part II

Compiled and Edited by Prof. Dr. N. Alper TAPAN

In our previous article, we briefly discussed the roots of machine learning (ML), which is a part of artificial intelligence dating back to the early 20th century, and briefly discussed also different machine learning techniques used, and how machine learning is applied in various fields. In this article, we will provide an example of an ML application in the field of direct alcohol fuel cells from our previous study [1] (This study was the first of its kind on application of machine learning on direct alcohol fuel cells although some data mining tools were applied on cathode materials of solid oxide fuel cells and mechanical behavior of polymer electrolyte fuel cells [2,3]) and demonstrate how machine learning is used to explore hidden and useful information from collected data or in another way of saying, how machine learning is used in data mining. In fact, these kind of data oriented strategies with open ended and growing database was aimed to help researchers for their future directions about fuel cells.

In our previous study [1], since observations are needed in order to train machine learning algorithm, database representing direct alcohol fuel cell (DAFC) performance was constructed by collecting representative 12 years of experimental polarization data (4682 observations) with selected (most frequently analyzed) features of DAFCs such as 41different catalytic, material and operational variables. At this point, it is necessary to point out that database construction is a critical step in machine learning because biased observations or observations not representing studies from various sources could lead to misleading model results which can not be generalized.

If the complex interactions between material, catalytic, operating variables in DAFCs are considered , it seems that it was almost impossible to reach a solution by either modeling and experimental works alone. Therefore by the combining the experience from the previous experimental works and ML techniques such as classification tree and artificial neural network, these complex relationships hidden in the previous observations was modelled to be used as suitable tools for future and more focused experimental studies. Therefore , we were able to determine the following tasks for DAFCs by these ML techniques:

-Routes to maximum power densities (high performances) by classification tree

-Prediction of polarization behavior (characteristic and critical behavior of the system) by ANN with given operational and catalytic variables

-Determination of dominant variables on the performance of DAFC by ANN.

Now lets briefly examine the two ML techniques used in this case study:

Classification tree

As we have mentioned in the previous montly issue ,classification tree is a supervised machine learning strategy. It gives hidden relationships between different classes of features after the model is trained and tested with a randomly selected set of observations [4]. There are many tools available like libraries in Python, ML toolbox in Matlab, packages in R or Rapidminer software etc. used for training and testing of decision tree models.

Basically, during execution of classification tree, observation sets are split recursively in the leaf nodes based on the desired purity criteria with best selected features at the root and branch nodes of the tree. Different algorithms were developed for construction of decision trees like ID3, CART, C4.5, C5.0 algorithms [5,6,7] that have different performance advantages like high classification speed, strong learning ability and simple construction.

The purity criterions (which is a hyperparameter in decision tree modelling) generally used in the softwares for evaluating the performance of decision trees are gini diversity index, twoing, deviance, information gain and node error. The performance of decision tree is also dependent on the right choice of purity criterion and different purity criterion could result in different classification accuracy.

The flow diagram of CART (classification and regression tree) decision tree algorithm for binary tree (meaning every branch has two children) can be represented as six steps shown below:

1) Examine all possible binary splits,

2) Select a split based on selected optimization criterion,

3) Check if the split meets the hyperparameters like # of observations in the leaf node

4) Apply the split

5) After the binary split, apply step 1 to 4 for child nodes,

6) Check the stopping rule: Is the node pure ?, Are there fewer observations than minimum # of parent observation(hyperparameter selected)?, Do the child nodes have fewer observations than MinLeaf observations (hyperparameter selected)?

Other than selection of purity criterion, the other most important factor in construction of optimum decision tree is overfitting and underfitting regions. If decision tree learner construct a very big tree of many leafs in order to perfectly fit the training data, the model would not be able to generalize the behaviour of model and would give high testing error (or low testing accuracy from test data: % correct prediction of classes) although training error would be low. Therefore the tree should be prunned to avoid overfitting of model and minimize testing error which could be achieved by setting a constraint for minimum number of samples at a leaf node or setting a maximum depth of the tree [5].

In our study [1] after determining testing errors for different sizes of prunned trees for maximum power density in DAFC, optimum size of tree with 31 leaf nodes was decided. In order to see the performance of decision tree , testing and training classification accuracies were compared for different classes of power density as shown in Fig. 1 below.

Fig. 1. Comparison of testing and training accuracies and # of predictions of optimum decision tree for classes of power density.

It is seen in Fig 1. that, testing accuracies exceed 70% although they are lower than training accuracies. With these training and testing accuracies, the optimum tree (Fig. 2) showed that the binary root node was the type of alcohol (ethanol, methanol-propanol) used as a fuel. The branch nodes for the case of methanol-propanol continued with cathode loading, temperature and by other variables. In the case of ethanol, anode variables were mostly deterministic for power density classes.

Fig. 2. A tree showing roots to high power density (red arrow shows the leaf node for high power density)

The routes to high power density leaf nodes (by red arrow)or rules for high classes in Fig. 2. can be extracted as seen below:

• high (1):Alcohol type: ethanol ,anode Sn composition >=0.05,anode loading =<5 mg/cm2, anode carbon composition =< 0.063, temperature >= 130oC, concentration of fuel >=1M

• high (2): Alcohol type: methanol-propanol, cathode loading >=2mg/cm2 , 55oC < temperature <85oC, concentration of fuel =< 13.1M, oxidant flow rate =< 100ml/min, anode loading >= 2mg/cm2.

• high (3): Alcohol type: methanol-propanol, cathode loading >=2mg/cm2, temperature =<55oC, anode loading >=3.3 mg/cm2, fuel flow rate >= 1ml/min, anode CNC (carbon nanocoil) composition >=0.006.

Artificial neural network

In the second part of our study [1], like classification tree as another machine learning technique, artificial neural network was applied to DAFCs to model polarization behavior and determine most important parameters for the performance.

In the case of ANN, before training of the model the architecture of ANN should be constructed. The architecture involves number of hidden layers and neurons in these hidden layers which are hyperparameters. The number of neurons on the output layer is equal to the number of output variables which was just the voltage of the fuel cell in our case. In order to optimize ANN model, the number of hidden layers (depth of ANN) and neurons in the hidden layers can be changed. In general, increasing the number of neurons (complexity increase) does not help for generalization of the data. After construction of the network architecture, the size of the training , testing and validation sets should be decided where of course training set is used to learn from the data, validation set is used to stop training to avoid overfitting if validation error increases for more than 6 epochs(epoch:one pass of running of ANN model over all training data) and testing set is used to test the performance of the model at every epoch which gives higher error values as training error continue to decrease(in ANN algorithm) [8].

Other than hidden layer and number of neurons, there is an other critical hyperparameter, activation function which is embedded in the hidden layer. There are different forms of activation function like rectified linear unit (ReLU), hyperbolic tangent sigmoid (tansig) etc. The default activation function can be set in softwares like for instance tansig in MATLAB environment. The activation function processes the weighted sum of input variables with the biases at the neurons in the hidden layers. Therefore during training, ANN model optimizes the weights and biases which are internal parameters in the neurons. In order to check the performance of ANN training, root mean squared error (RMSE) shown in Eq.1 can be used. (1)

(1)

In Eqn 1, Ytrain and Ytrue are predicted and observed values in training set. In general RMSE values less than 0.1 is desirable for a high performance model. In order to check the prediction performance of ANN, coefficient of determination R2 value can also determined and R2 value close to 1 is desirable.

In our DAFC study [1], we were able to predict three unseen polarization behavior from literature [9-11] with R2 values 0.978, 0.95, 0.96 with 2 hidden layer and 16 neurons in each hidden layer. Actually, high ANN model performance on the unseen data (which can be set a side before testing and training ANN model) shows the strength of the model for generalization.

In order to determine important or influential variables on system performance, RMSE values were determined in the absence and presence of selected variables. The difference between RMSE values in the absence and presence of selected variable is an important indicator for the dominance of that variable for the polarization behavior (system behavior). In the Fig. 3 below, the RMSE differences of the DAFC features are presented for our shallow ANN. Fig. 3. shows that the three most important variables on polarization behavior of DAFC except current density are anode electrocatalysts, temperature and concentration of fuel.

Fig. 3. RMSE difference in polarization behavior from predicted ANN model for various DAFC operating, catalytic and material variables.

In conclusion, we hope that this case study encapsulates the essence of the machine learning approach, offering inspiration to researchers interested in integrating ML techniques into their catalytic studies and hope that it serves as a stepping stone for researchers towards the advancement of artificial science.

The following resources below can be used for further reading.

[1] Tapan, N. A., Günay, M. E., & Yildirim, R. (2016). Constructing global models from past publications to improve design and operating conditions for direct alcohol fuel cells. Chemical Engineering Research and Design, 105, 162-170.

[2] Grondin, D., Deseure, J., Ozil, P., Chabriat, J.P., Grondin-Perez, B.,Brisse, A., 2013. Solid oxide electrolysis cell 3D simulationusing artificial neural network for cathodic processdescription. Chem. Eng. Res. Des. 91, 134–140.

[3] Paclisan, D., Charon, W., 2013. Real time modelling of thedynamic mechanical behaviour of PEMFC thanks to neuralnetworks. Eng. Appl. Artif. Intell. 26, 706–713.

[4] Myles, A. J., Feudale, R. N., Liu, Y., Woody, N. A., & Brown, S. D. (2004). An introduction to decision tree modeling. Journal of Chemometrics: A Journal of the Chemometrics Society, 18(6), 275-285.

[5] Brijain, M., Patel, R., Kushik, M. R., & Rana, K. (2014). A survey on decision tree algorithm for classification.

[6] Quinlan, J. R. (1986). Induction of decision trees. Machine learning, 1(1), 81-106.

[7] Breiman, L., Friedman, J. H., Olshen, R. A., & Stone, C. J. (1984). Classification and Regression Trees. Chapman and Hall/CRC. doi:10.1201/9781315139470

[8] Demuth, H., Beale, M., & Hagan, M. (1992). Neural network toolbox. For Use with MATLAB. The MathWorks Inc, 2000.

[9] Antolini, E., 2007. Catalysts for direct ethanol fuel cells. J. PowerSources 170, 1–12.

[10] Chetty, R., Scott, K., 2007. Direct ethanol fuel cells with catalysedmetal mesh anodes. Electrochim. Acta 52, 4073–4081.

[11] Baglio, V., Sebastián, D., D’Urso, C., Stassi, A., Amin, R.S.,El-Khatib, K.M., Aricò, A.S., 2014. Composite anode electrodebased on iridium oxide promoter for direct methanol fuelcells. Electrochim. Acta 128, 304–310.

Recent Selected Papers in our Catalysis Community

In recent months, there have been exciting research studies in catalysis research in Turkey. Here are the short summaries:

CO2 electroreduction

Dongare, S., Zeeshan, M., Aydogdu, A. S., Dikki, R., Kurtoğlu-Öztulum, S. F., Coskun, O. K., ... & Gurkan, B. (2024). Reactive capture and electrochemical conversion of CO 2 with ionic liquids and deep eutectic solvents. Chemical Society Reviews.

Ionic liquids (ILs) and deep eutectic solvents (DESs) are promising for reactive capture and conversion (RCC) of CO2 due to their stability, low volatility, and high CO2 solubility. They enable direct utilization of captured CO2 using electrified processes without the need for compression, transportation, or storage, unlike conventional electrochemical conversion methods with aqueous electrolytes. This review discusses the tuning of ILs and DESs for RCC, highlighting their chemisorption and electroreduction mechanisms, and evaluates their potential through a techno-economic lens.

Coupling reactions

Nawaz, Z., Gürbüz, N., Zafar, M. N., Tahir, M. N., Özdemir, İ., & Trovitch, R. J. (2024). Design of Efficient Benzimidazole-Derived N-Heterocyclic Carbene Ag (I) Catalysts for Aldehyde-Amine-Alkyne Coupling. Journal of Molecular Structure, 139239.

A mild catalytic protocol for aldehyde, amine, and alkyne coupling (A3-coupling) selectively synthesizes propargyl amines using 5,6-dimethylbenzimidazole-derived N-heterocyclic carbene (BNHC) silver(I) catalysts. BNHC Ag(I) halide complexes were synthesized and characterized by multinuclear NMR, FT-IR spectroscopy, and single-crystal X-ray diffraction. This silver-based A3-coupling method achieves up to 95% yield for propargyl amines with environmentally benign conditions, producing only water as a byproduct.

Şahin, N., Zengin, S., Özdemir, İ., & Sémeril, D. (2024). CH activation of furanyl and thiofuranyl substrates catalyzed by trans-dichloro [1-cinnamyl-3-arylmethyl-benzimidazol-2-yliden] pyridine palladium (II) complexes. Polyhedron, 117144.

This study investigates six NHC-palladium(II) complexes derived from N-cinnamyl-N’-alkylbenzimidazolium salts as precatalysts for cross-coupling reactions between furanyl and thiofuranyl derivatives and arylbromides via C-H activation. The structures of these complexes were elucidated using multinuclear NMR, FT-IR, and mass spectroscopy, with the square-planar geometry confirmed by single crystal X-ray diffraction for complex 3c. Complex 3c was the most effective precatalyst, achieving conversion rates higher than 78% with 4-bromoacetophenone and 1-bromonaphthalene.

Kizilkaya, A. C., Martínez-Monje, M. E., & Prieto, G. (2024). Synthesis of Acetonitrile from NH3/Syngas Mixtures on Molybdenum Nitride: Insights into the Reaction Mechanism. Catalysis Today, 114947.

Transition metal nitrides, with their metallic-like surface electronic properties and ability to act as reservoirs and transfer agents for active nitrogen, are promising solid catalysts for C-C and C-N coupling reactions, facilitating the production of higher nitrogenated chemicals from unconventional carbon resources. Experimental and computational studies reveal that an oxidic MoO3 catalyst precursor undergoes in situ nitridation at 723 K to form the active Mo2N catalyst, which facilitates hydrogen-assisted CO dissociation and the formation of acetonitrile from syngas/ammonia mixtures. Density Functional Theory indicates that HCN is a major intermediate in this process, with the dissociation of HCN and the role of surface oxygen species being key factors in the reaction pathway and overall kinetics.

Zeolites

Zeybek, E., Irmak, B., Ulusoy, S., & Uraz, C. (2024). Increasing the Anticorrosive Property of Zinc Plating Process with Modified Zeolite. Journal of Engineering Research and Applied Science, 13(1), 2483-2489.

The study aims to enhance corrosion resistance, reduce costs, and improve eco-friendliness in alkaline zinc plating by incorporating modified zeolites. Different chemicals and zeolite variations were used for modification, and their effectiveness was evaluated through corrosion tests and characterization via FT-IR and SEM analysis. The most effective anticorrosive modification was achieved with 7 grams of 10 µm zeolite and molybdic acid, demonstrating the best results in preventing red rust formation.

Upcoming Catalysis Events

30 days left to 7th Anatolian School of Catalysis (Date: 01-05/09/2024)

Don’t forget to register and check out updated web page below!!

Sponsored by European Federation of Catalysis (EFCATS)!!

Web site: https://meetinghand.com/e/7th-anatolian-school-of-catalysis-asc-7/

The 35th National Chemistry Congress with special session on Catalysis (Date: 09-12/09/2024)

Web site: https://kimya2024.com/

Don't miss out! Register now for these events and be part of the catalysis community.