Dear Catalysis Researchers,

Welcome to our monthly newsletter Magic Powder dedicated to catalysis research and development.

This September 2024 period was highly productive in terms of catalysis science.

From September 1-5, 2024, our Catalysis Association successfully organized the 7th Summer School at İzmir Institute of Technology (Urla) under the chairmanship of our esteemed members, Dr. Başar Çağlar and Dr. Samira F. Kurtoğlu Öztulum. The event was highly productive, enjoyable, and fruitful, scientifically and socially, with the participation of world-renowned scientists and industry experts. The number of registered master's and doctoral students, as well as academics, reached 67. In addition, 20 invited scientists and 24 industry experts attended as speakers. Presentations covered topics such as the fundamentals and history of catalysis, catalyst synthesis techniques, in-situ and synchrotron catalyst characterization, industrial catalytic processes, homogeneous and heterogeneous catalysts, bio-, electro-, and photocatalysts, sustainable and green catalytic processes, and computational catalysis. We also held a panel discussion on publishing and writing, the relationship between industry and catalysis research, and competition and exploration in catalysis research. All information about our summer school, including the downloadable book of abstracts, can be accessed at https://meetinghand.com/e/7th-anatolian-school-of-catalysis-asc-7/#book-of-abstracts-3998.

From September 9-12, 2024, under the coordination of the Turkish Chemical Society and in collaboration with the Chemistry Departments of İnönü University Faculty of Science and Letters and Dicle University Faculty of Science, the 35th National Chemistry Congress was held in Diyarbakır. The congress featured renowned scientists from Turkey and around the world as invited speakers. On September 10-11, 2024, catalysis sessions were organized, covering various topics such as photocatalysts, hydrogen production catalysts, biodiesel, the oxidative coupling of methane reaction, dehydrogenation, carbon-based catalysts, reduction, and biocatalysts. Our association's president, Prof. Dr. Ayşe Nilgün Akın, and the president of the Turkish Chemical Society, Prof. Dr. Bahattin Yalçın, also discussed opportunities for future collaborations in catalysis congresses, summer schools, and other association activities.

In this issue,

-First of all, we will introduce the Gazi University Chemical Reaction Engineering Research Laboratory (Page 3-16).

-Secondly, as a tradition, you can see short summaries of the most recent high-impact research articles conducted by the Turkish Catalysis Community (Page 17).

-Finally, a brief overview of the “Applied Catalysis Seminar” organized by the Department of Chemical Engineering at Ondokuz Mayıs University has been presented (Page 19).

And thanks a lot for being part of our catalysis community. We look forward to bringing you more exciting updates in the next edition of our newsletter. We are always open to contributions from academic and industrial partners in our upcoming issues.

Editorial Board:

Prof. Dr. Ayşe Nilgün AKIN

Prof. Dr. N. Alper TAPAN

Dr. Merve Doğan ÖZCAN

Dr. Elif Can ÖZCAN

Dr. Mustafa Yasin Arslan

Contact info:

Email:katalizdernegi@gmail.com

Linkedin: https://www.linkedin.com/in/kataliz-derneği-272879a

GAZİ UNIVERSITY CHEMICAL REACTION ENGINEERING GROUP (CREG)

Gazi University Chemical Reaction Engineering Research Laboratory is a laboratory where undergraduate and graduate students actively participate and produce many qualified projects supported by DPT, TÜBİTAK, and Gazi University Scientific Research Projects Fund (BAP). Our laboratory was first established by Prof. Dr. Gülşen Doğu with project support from different institutions to conduct research in the field of chemical reaction engineering and to provide education especially to graduate students. Research on a wide range of topics has been carried out with the other faculty members who participated in the working group. Our studies are carried out with the support of many national and international projects and in various joint studies in cooperation with different universities.

Some of the research conducted in the Chemical Reaction Engineering Laboratory included hydrogen production from different sources such as methanol, ammonia, H2S, and methane; isobutane dehydrogenation; biofuel production from bio-oil; synthesis gas production; olefin production, fuel, and fuel additives production, and machine learning, etc.

On this bulletin, we would like to express our sincere thanks to our esteemed professors, Prof. Dr. Gülşen Doğu and Prof. Dr. Timur Doğu, for the path they have opened for us in academic life, their contributions, their support and they’re always being by our side.

CREG Members

Prof. Dr. Gülşen DOĞU

Prof. Dr. Kırali MÜRTEZAOĞLU

Prof. Dr. Nail YAŞYERLİ

Prof. Dr. Nuray OKTAR

Prof. Dr. Sena YAŞYERLİ

Prof. Dr. Meltem DOĞAN

Prof. Dr. Alper TAPAN

Prof. Dr. Dilek VARIŞLI

Prof. Dr. Hüseyin ARBAĞ

Prof. Dr. Saliha ÇETİNYOKUŞ

Assoc. Prof. Dr. H. Mehmet TAŞDEMİR

Asst. Prof.Dr. Emine EKİNCİ

Asst. Prof.Dr. Birce PEKMEZCİ KARAMAN

Res. Asst. Dr. Pınar DEĞİRMENCİOĞLU

Res. Asst. Merve ÇELİK ÖZCAN

Res. Asst. Mert Yekta DOĞAN

Res. Asst. Hale AKANSU

The most recent research topics of research group led by experts in different research fields are listed as follows:

1. Production of Light Olefins from Methanol

This research system is dedicated to the synthesis of catalysts for the conversion of methanol into light olefins, namely ethylene and propylene under atmospheric pressure. The goal is to obtain these valuable monomers in a highly selective manner together with a reduced coke formation using the synthesized HZSM-5-based catalysts. Activity tests are performed in a fixed-bed continuous-flow reactor system. Studies are financed by “FYL-2023-8394 Kinetic Studies on the Synthesis of Light Olefins from Methanol” within the scope of Gazi University Scientific Research Projects (BAP).

Related Research Paper on the Production of Light Olefins from Methanol:

[1] Degirmencioglu, P., Arbag, H., (2023). Acid Treatment to Improve Total Light Olefins Selectivity of HZSM-5 Catalyst in Methanol to Olefins (MTO) Reaction. Arabian Journal for Science and Engineering, 48,16123.

2. Production of Hydrogen from Methanol

Hydrogen has the highest energy content per unit mass among all known fuels. Conventionally, hydrogen can be produced by steam reforming reactions and partial oxidation of fossil fuels or natural gas. Methanol can be produced with sustainable biomass, and its reserves and transportation are also simple and safe. There are four routes to produce hydrogen from methanol, namely methanol decomposition reaction (CH3OH → CO + 2H2), methanol partial oxidation reaction (CH3OH + 1/2O2 → CO2 + 2H2), methanol steam reforming reaction (CH3OH + H2O → CO2 + 3H2) and oxidative steam reforming reaction (4CH3OH + 3H2O + 1/2O2 → 4CO2 + 11H2). Especially methanol decomposition reaction, which is carried out at lower temperatures, exhibits operational convenience and economic advantage among these reactions. Thus, it is used in small-scale hydrogen production and recovery of waste heat from industries and automobiles. The scope of the study is on the development of active and stable catalysts for hydrogen production by methanol cracking reaction. Copper-containing catalysts are used for this reaction in the literature, but these catalysts are not stable due to their low sintering temperatures. For this purpose, catalyst synthesis, characterization, and activity test studies are carried out.

Progressing studies are financed by “FDK-2023-8907 Development of Catalyst for Hydrogen Production from Methanol” within the scope of Gazi University Scientific Research Projects (BAP).

3. Production of Bio-fuel from Bio-oil

Development and Application of Novel Catalysts Resistant to Carbon Formation to be used in Biofuel Production

In this study, biofuel production was carried out using a model bio-oil mixture. Bio-oil is unsuitable for direct fuel use due to its high oxygen content, low heating value, and thermal instability. Therefore, upgrading studies were carried out via catalytic methods for the use of bio-oil as an alternative liquid fuel. During the reaction studies, product formation was observed in both gas and liquid phases. Important hydrocarbon compounds in terms of fuel content are located in the liquid phase. CO, CO2, and C1-C4 hydrocarbons were observed due to deoxygenation in the gas phase. Activity test studies were carried out in the presence of alumina, silica microsphere, and HZSM-5-supported catalysts. Metal-containing catalysts were prepared by co-impregnation and sequential impregnation methods. The effects of catalysts on the conversion of bio-oil components and fuel phase selectivity were investigated. Analysis of products in gas and liquid phases was carried out using gas chromatography. As a result of the activity test studies, the collected fuel phase was classified in terms of hydrocarbon types by flame ionization detector (FID). The gas products formed during the reaction were analyzed online in a gas chromatography device equipped with a thermal conductivity detector (TCD).

The experimental system for biofuel production from bio-oil was established within the scope of the TUBITAK-1001 project with code 219Z232. Activity tests for bio-fuel production are conducted in a fixed-bed continuous flow reactor system as shown in Figure 1. Progressing thesis studies are financed by the project FDK-2024-9608 within the scope of Gazi University Scientific Research Projects (BAP). The experimental system is actively operating. The TUBITAK-1001 project has been completed successfully. Also, Studies are financed by “FGA-2022-7709 Biofuel Production with Active Metal-Containing Silica Microsphere Catalysts” within the scope of Gazi University Scientific Research Projects (BAP).

Figure 1. Experimental Setup Used for Bio-oil to Bio-fuel Production

Related Research Papers about Bio-fuel Production

[1] Ozcan, M. C., Degirmencioglu, P., Ekinci, E., Karaman, B. P., Murtezaoglu, K., & Oktar, N. (2024). Effect of the amount and type of active metal and its impregnation sequence on bio-fuel production. Applied Catalysis A: General, 683, 119850.

[2] Guvenc C., Alan E., Degirmencioglu P., Celik Ozcan M., Pekmezci Karaman B., Oktar N. (2023). Catalytic upgrading of bio-oil model mixtures in the presence of microporous HZSM-5 and γ-Al2O3 based Ni, Ta, and Zr catalysts. Fuel,350, 128870.

[3] Karaman, B. P. (2024). Nickel and cobalt incorporated mesoporous HZSM-5 catalysts for biofuel production from bio-oil model compounds. Research on Chemical Intermediates, 50(9), 4465-4483.

4. On-site Hydrogen-Rich Gas Production from Diesel

This study was conducted with university-industry collaboration, it was aimed to develop a reforming catalyst with reduced deactivation achieving continuous on-site hydrogen-rich gas production using Diesel fuel as the hydrogen source. The study aimed to investigate the impact of nickel-incorporating diverse metal oxides (MgO, La2O3, CeO2, SiO2) supported on alumina on the Diesel steam reforming reaction. The main components which are used in reforming experiments are presented in Figure 2.

Figure 2. Diesel Steam Reformer Set-up

Progressing thesis studies are financed by “FHD-2023-8622 Investigation of Diesel Reformation Reaction in Pilot Scale System” within the scope of Gazi University Scientific Research Projects (BAP).

Related Research Paper about Diesel Steam Reforming

[1] Sahingoz, N. C., Talu, K., Oktar, N., Dogu, T., & Pamuk, I. (2024). On-site hydrogen-rich gas production from diesel: A comprehensive study on catalyst development with nickel and diverse metal oxides (MgO, La2O3, CeO2, SiO2) supported on alumina. Applied Catalysis A: General, 687, 119940.

5. Synthesis Gas Production by the Dry Reforming of Methane

The dry reforming of methane with carbon dioxide is a highly endothermic reaction (R.1). The molar ratio of hydrogen and carbon monoxide gases in the obtained synthesis gas is approximately equal, allowing the reaction products to be used as raw materials in various processes such as the production of liquid synthetic fuels by the Fischer-Tropsch method. In addition to the main reaction, side reactions such as reverse water gas shift reaction, steam reforming and methanation (R.2, R.3, and R.4) can affect the H2/CO ratio (Figure 3). Sulfur poisoning caused by trace amounts of H2S gas in the biogas (R.7 and R.8) and carbon deposition (R.5 and R.6) are the main drawbacks for catalytic deactivation. Ni-based catalysts are frequently preferred due to availability, low cost, and activity. However, the development of Ni-based catalysts is a key problem for producing syngas because they are not resistant to coke deposition/formation and sulfur poisoning.

Figure 3. Synthesis gas production by the dry reforming reaction

In the studies carried out by the research group within the scope of the TUBITAK-1001 projects, (Project Numbers: 107M066, 111M449) sol-gel alumina and MCM-41 supported nickel-based catalysts were investigated. Also, Mn, Fe, and Ce were added to the catalyst structure to increase the resistance of Ni-based catalysts against coke deposition, sintering, and sulfur poisoning (Project Number: 218M380). Some recent publications are given below:

Related Research Papers about Dry Reforming of Methane:

[1] Dogan, M. Y., Arbag, H., Tasdemir, H. M., Yasyerli, N., Yasyerli, S. (2023). Effect of ceria content in Ni–Ce–Al catalyst on catalytic performance and carbon/coke formation in dry reforming of CH4. International Journal of Hydrogen Energy, 48(60), 23013-23030.

[2] Akansu, H., Arbag, H., Tasdemir, H. M., Yasyerli, S., Yasyerli, N., Dogu, G. (2022). Nickel-based alumina supported catalysts for dry reforming of biogas in the absence and the presence of H2S: Effect of manganese incorporation. Catalysis Today, 397, 37-49.

[3] Genc A., Arbağ H., Taşdemir H. M., Yaşyerli N., Yaşyerli S. (2023). Investigation of effects of sulfur on dry reforming of biogas over nickel–iron-based catalysts. International Journal of Hydrogen Energy, 48 (60), 23031-23043.

6. COx-Free Hydrogen Production by Decomposition Reaction of H2S

H2S gas is a highly corrosive and toxic gas released from industrial processes. In the chemical industry, H2S is converted into water vapor and elemental sulfur products by Claus Process. Nowadays, researchers have focused their studies on obtaining hydrogen and elemental sulfur products by one-step H2S thermal catalytic decomposition reaction (Figure 4). With this reaction, both green hydrogen production without carbon emission and elemental sulfur production can be achieved. This reaction is reversible and due to its endothermic nature, high energy is required to achieve high H2S conversions.

Figure 4. COx-free hydrogen production by one-step catalytic H2S decomposition

In the ongoing project, alumina and activated carbon supported catalysts are prepared and tested for H2S decomposition in one-step conventional and/or microwave heating systems. This study was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under Grant Number 122M400. The authors thank TUBITAK for their support. Some of the results obtained from the project are published in the article given below.

Related Research Papers about the Decomposition of H2S

[1] Dogan, M. Y., Tasdemir, H. M., Arbag, H., Yasyerli, N., & Yasyerli, S. (2024). H2 production via H2S decomposition over activated carbon supported Fe- and W-catalysts. International Journal of Hydrogen Energy, 75(19), 483-495.

7. Cr- based Catalyst Synthesis for Isobutane Dehydrogenation

In the research group, studies are carried out on the direct dehydrogenation of isobutane to isobutene, the oxidative dehydrogenation of isobutane, and membrane reactor applications for these reactions. Recently, studies have also begun to obtain isobutene from synthesis gas.

Depending on the development of technology, the demand for valuable products (MTBE, ETBE, BHT, BHA, PIB etc.) has increased, and isobutane dehydrogenation has become an important alternative. Isobutane dehydrogenation is an endothermic equilibrium-limited reaction. High temperatures are required for high conversions. High temperatures, on the other hand, favor coke formation and require frequent regeneration of the catalyst. The reaction at high temperatures causes catalyst deactivation and many side reactions. Catalyst synthesis with high activity, selectivity, and stability is important for this reaction. The reaction proceeds on catalysts with various active components (Pt, V, Cr, Ga, Fe), but the Cr active component attracts attention with its cheapness and suppression of coke formation for the reaction. The different types of Cr that will form on the catalyst are strongly dependent on the preparation method, starting material, and Cr-support interaction. In the study conducted by the research group [1], the effects of Cr content on the catalyst structure, chromate types, and amounts were investigated. The catalyst support MCM-41 was synthesized hydrothermally, and then xCr@MCM-41 (x:4,6,8,10) catalysts in different mass% ratios were prepared by the impregnation technique. The highest amount of active monochromates for the reaction was detected in the 4Cr@MCM-41 catalyst. Catalytic tests (600°C, atmospheric) were performed on the 4Cr@MCM-41 catalyst, which was selected for its suitable crystal size, homogeneous metal distribution, and high amount of active monochromate. High isobutane conversions (80%) were obtained up to the 60th minute, and high isobutene selectivity (95%) after the 40th minute. The observed high conversions were explained by the conversion of Cr(II)O2-2s formed by tetrahedral coordinated Cr(VI)O4-2 structures in the catalyst into active Cr(III)O3-3 species by using the water in the support structure. In addition, it was shown that this form change reduced the surface acidity of the catalyst, especially the Lewis acid sites, thus increasing the selectivity of isobutene and preventing the formation of coke. It was found that 4% by mass of Cr content from the synthesized xCr@MCM-41 catalysts were suitable for high isobutene selectivity and high amount of monochromate formation. It was aimed to determine the effect of chromium concentration in the catalyst structure on the chromate types and chromium oxidation states in another study conducted by the research group [2]. The MCM-41-supported chromium oxide catalysts at different chromium concentrations (4–10 % by mass) were synthesized hydrothermally. It was shown that inactive α-Cr2O3 crystals for isobutane dehydrogenation increased in the catalyst structure as the chromium loading increased. The highest amount of Cr6+ on the catalyst surface was detected in the catalyst with 4 % chromium by mass. Catalytic tests (T = 600 °C, P = atmospheric pressure, WHSV = 26 h–1) were carried out under fixed bed reactor conditions. The highest isobutane conversion (~60 %) and selectivity (~80 %) were determined on the H4-MCM-41 catalyst, which had the highest amount of Cr6+ and monochromate structures. It was indicated that catalyst deactivation was not due to coke deposition but, rather, was caused by the formation of inactive α-Cr2O3 crystal structures.

The process of oxidative dehydrogenation of light alkanes can utilize heterogeneous catalysis in the presence of carbon dioxide (CO2). This approach is sustainable and environmentally friendly as CO2 is a softer and controllable option for converting light alkanes into olefins. By introducing an oxidizing agent to the dehydrogenation reaction environment, the hydrogen produced during the process can be oxidized, which helps to reduce the occurrence of side reactions such as alkane cracking and coke formation. In the research group study [3], chromium-based catalysts on titanium-modified MCM-41 were synthesized for oxidative dehydrogenation reactions. To increase the hydrothermal stability of support, titanium was added to the MCM41. The hydrothermal stability test indicated that the loading of titanium improved the stability of MCM-41. Chromium-based catalysts on titanium-modified MCM-41 were prepared by wet impregnation method at different chromium loading (3% and 10%, by mass). The highest isobutane conversion (94%) and isobutene selectivity (81%) values were obtained for catalyst supported on Ti-modified MCM-41. High activity predicted for catalyst supported on modified MCM-41 was explained by improving hydrophilic properties.

Related Research Papers about Cr- based Catalyst Synthesis for Isobutane Dehydrogenation:

[1] Çetinyokuş Kılıçarslan, S., Doğan, M., Erol, Z. (2021). Investigation of the effectiveness of Cr@MCM-41 catalysts in isobutane dehydrogenation, Journal of the Faculty of Engineering and Architecture of Gazi University, 36(2), 1075-1088.

[2] Erol, Z., Çetinyokuş Kılıçarslan, S., Doğan, M. (2020). Investigation of isobutane dehydrogenation on CrOx/MCM-41 Catalyst. Macedonian Journal of Chemistry and Chemical Engineering, 39(1), 109–118.

[3] Mosa, H.M.Y., Dogan, M., Cetinyokus, S. (2024). Synthesis and characterization of chromium-b Catalysts on titanium-modified-MCM-41 for oxidative dehydrogenation of isobutane. Bitlis Eren University Journal of Science and Technology, 14(1), 1-22.

8. Investigation of Isobutane Dehydrogenation in Pd-based Membrane Reactors

Pd and Pd alloy membranes, which are highly selective towards hydrogen, are widely used in dehydrogenation and hydrogenation reactions. Pd membranes must have a certain thickness to maintain their mechanical strength and when made thin enough they can provide adequate flow for hydrogen. It is recommended to use palladium in alloys with other metals to increase hydrogen permeability. It was aimed to synthesize PdCu alloy membranes with firm, thin, and fcc phase structures (resistant to sulfur compounds), selectively permeable to hydrogen, using an electroless plating technique by creating an osmotic flux by the research group [1]. First, coating studies were conducted without creating osmotic flux to determine the appropriate alloy formation temperature. Commercial porous borosilicate glass tubes were modified with alumina to form an interface that enhances the interaction between the coating and the support. Afterward, coating studies were conducted by creating an osmotic flux with a 3 M sucrose solution, keeping the coating conditions and bath composition the same. By the literature, low hydrogen flux (0.04–0.09 mol/m2 s) and high selectivity values (αH2/N2:465–324) were determined in membranes synthesized with osmotic flux. Additionally, it was determined that this membrane remained stable in the hydrogen environment (T = 250 °C, ΔP = 203 kPa) for 96 h. The results of the study showed that conducting the electroless plating method with osmotic flux made positive contributions to the structure and hydrogen selectivity of the prepared alloy membranes.

Membrane reactors are reactors that perform catalytic reactions and separation processes in one step. This combination reduces the number of reactors, and the amount of catalyst and makes the process more efficient. The use of membrane reactors in equilibrium-limited dehydrogenation reactions is remarkable. One of the studies [2], it was aimed to overcome the equilibrium conversions by using a membrane reactor. First, Al2O3-supported chromium-based catalysts were prepared by the impregnation technique. Then, reactions were performed with a catalyst containing 8% by mass of Cr, which was prepared in a mixing time of 48 h with the highest amount of monochromate. The reactions were carried out in a Pd-based membrane reactor system with pure isobutane feed. The effect of reactor temperature was investigated at 550 °C and 600 °C (WHSV:0.3h−1). While no significant difference was observed between the conversion values at both reactor temperatures (⁓90%), isobutene selectivity values were higher (⁓85%) at 600 °C. The presence of less hydrogen in the environment decreased the formation of the hydrogenation reaction of isobutane. This situation enhanced an increase in isobutene selectivity values. The results of the modeling studies carried out in the membrane reactor were found to be compatible with the experimental results.

Related Research Papers about Isobutane Dehydrogenation in Pd-based Membrane Reactors:

[1] Kilic, S., Dogan, M., Cetinyokus, S. (2023). Effects of osmotic flux on PdCu alloy membrane structure. Arabian Journal for Science and Engineering, 48, 8887–8899.

[2] Erdali, A.D., Cetinyokus, S., Dogan, M. (2022). Investigation of isobutane dehydrogenation on CrOx/Al2O3 catalyst in a membrane reactor. Chemical Engineering and Processing - Process Intensification, 175, 108904.

9. Computational and Electrochemical Studies

Data mining strategies have emerged as a transformative trend in recent years across various scientific fields, ranging from astronomy and biology to economics. These techniques hold significant promise for advancing fuel cell technologies as well. In the research, we apply data mining strategies and machine learning techniques to the field of electrocatalysis, leveraging these powerful tools to unlock new insights. The studies span a wide range of applications, from biodiesel production and food science to cutting-edge fuel cell research and even to SARS-CoV-2 glucometer. Such data-driven approaches not only provide robust frameworks for analyzing complex experimental data but also help researchers identify promising directions for future fuel cell technologies. With the ever-expanding scientific literature, these strategies are invaluable for navigating and building upon the growing body of knowledge. The research focuses on the collection, filtering, and visual analysis of experimental observations, alongside the application of both supervised and unsupervised machine learning methods. These include techniques like regression, classification trees, artificial neural networks, Gaussian process regression, association rule mining, and SHAP (SHapley Additive exPlanations), among others. We employ a variety of software tools such as AutoQSAR, Shapash, Python libraries, MATLAB tools, and custom code to enhance the scope and accuracy of the analyses. Below are some of the recent publications, showcasing the ongoing efforts in applying machine learning to fuel cell technology and other areas:

Related Research Papers about Computational and Electrochemical Studies:

[1] Günay, M. E., & Tapan, N. A. (2024). Analysis of CO selectivity during electroreduction of CO2 in deep eutectic solvents by machine learning. Journal of Applied Electrochemistry, 54(7), 1541-1556.

[2] Gürbüz, T., Günay, M. E., & Tapan, N. A. (2024). Machine learning solutions for enhanced performance in plant-based microbial fuel cells. International Journal of Hydrogen Energy, 78, 1060-1069.

[3] Günay, M. E., & Tapan, N. A. (2023). Evaluation of polymer electrolyte membrane electrolysis by explainable machine learning, optimum classification model, and active learning. Journal of Applied Electrochemistry, 53(3), 415-433.

[4] Günay, M. E., & Tapan, N. A. (2023). Analysis of PEM and AEM electrolysis by neural network pattern recognition, association rule mining, and LIME. Energy and AI, 13, 100254.

[5] Tapan, N. A., Günay, M. E., & Yıldırım, N. (2023). Application of Machine Learning for the Determination of Damaged Starch Ratio as an Alternative to Medcalf and Gilles Principle. Food Analytical Methods, 16(3), 604-614.

[6] Tapan, N. A. (2022). Application of Gaussian process regression and asymmetric least squares baseline algorithm on the determination of electrochemical sensor characteristics: A case study on SARS-CoV-2 glucometer. Chemometrics and Intelligent Laboratory Systems, 230, 104677.

[7] Günay, M. E., Türker, L., & Tapan, N. A. (2019). Significant parameters and technological advancements in biodiesel production systems. Fuel, 250, 27-41.

10. Microwave Reactor Technology for Catalytic Reaction Studies

In the laboratory, a microwave reactor system has been used for catalytic decomposition of non-carbonaceous, such as ammonia, as well as carbonaceous feed, such as methane, to produce hydrogen with high purity. For this aim, we are also working to synthesize novel heterogeneous catalysts. Microwave reactor system provides different advantages, such as lower reaction temperature for higher conversion and selectivity, easy control, and energy efficiency, as compared to conventionally heated reactor systems, especially for endothermic reactions. A photograph of the experimental setup is shown in Figure 5. The microwave reactor (MW) operated continuously, using a microwave generator (supplied by SAIREM) with up to 2 kW power at 2.45 GHz, a magnetron, a chiller to cool the system, and a microwave heating chamber where the quartz reactor was placed. The reaction temperature was easily adjusted by modifying the power input to the generator. One key advantage of the microwave system was its ability to increase the reactor temperature from room temperature to 300°C in under a minute. We also compare the results obtained with a microwave reactor system with the ones obtained using a conventional system. The conventional system used for comparison is an electrically heated tubular furnace. In both setups, a gas chromatograph with a thermal conductivity detector (TCD) enabled online analysis of reactants and products.

Figure 5. Microwave Reactor system present in Chemical Reaction Engineering Research Laboratory

The studies on the application of microwave reactor system on ammonia decomposition is the pionner of this field (Applied Catalysıs B-Environmental, 2017, 201, pp.370; Applied Catalysis B-Envıronmental 2017, 219, pp.173). Recently, we have a project for methane cracking to produce COx-free hydrogen as well as high-value-added solid carbon, supported by the TUBITAK 1001 Grant (2023-2025). Although it is still an ongoing process, the current findings show potential for contributing to the literature, especially on the effects of microwave reactor technology and the catalyst that has little to no prior application in this reaction. With this project, there will be a new approach and a new research direction for the reaction of the catalytic decomposition of methane.

Here you can kindly find, some of the recent studies on the application of microwave reactor technology for catalytic reactions;

Yildiz, Z. N., & Varisli, D. (2024). Conversion of ammonia to hydrogen in the microwave reactor system using Mo@ Alumina catalysts with the promotion of rare-earth and alkaline earth elements. Renewable Energy, 228, 120603.

The study explored ammonia decomposition for high-purity hydrogen production using microwave reactor technology. Molybdenum catalysts supported on γ-Al₂O₃ were enhanced with alkaline-earth (calcium and barium) and rare-earth (lanthanum, cerium) elements as promoters. The benefits of microwave heating contributed to higher ammonia conversion rates in the microwave reactor compared to conventional methods. The large CaO crystals in 10Mo–4Ca@Al₂O₃ and dispersed La₂O₃ crystals, though limited in quantity, did not enhance catalytic activity. Conversely, 10Mo–4Ba@Al₂O₃ and 10Mo–4Ce@Al₂O₃ showed superior activity, particularly at lower temperatures like 350°C. Beyond this temperature, nearly complete conversion was observed for all promoted catalysts, with optimal Ba and Ce loadings found to be 4 wt%. A long-term stability test showed that 10Mo–4Ce@Al₂O₃ retained its activity over 720 minutes.

Seyfeli, R. C., & Varisli, D. (2022). Performance of microwave reactor system in decomposition of ammonia using nickel-based catalysts with different supports. International Journal of Hydrogen Energy, 47(34), 15175-15188.

The study examines the ammonia decomposition reaction to generate COx-free hydrogen using a microwave reactor system with nickel-based catalysts. Under microwave reactor conditions, the alumina-supported nickel catalyst (Ni@Alumina) outperforms the activated carbon-supported nickel catalyst (Ni@AC), though it shows lower performance in conventional testing. Selective heating of nickel species in Ni@Alumina enhances its performance in the microwave reactor. Meanwhile, the high surface area and small nickel particles in Ni@AC result in higher activity in the conventional reactor. Both Ni@Alumina and Ni@AC exhibit reduced activity with conventional heating compared to microwave heating, with hot spot formation and the microwave-selective catalytic effect identified as potential reasons for the improved performance.

Akca, M., & Varisli, D. (2020). Performance of Co-Fe@ Alumina catalysts in comparison to monometallic Co@ Alumina and Fe@ Alumina catalysts for microwave assisted COx-free hydrogen production. Molecular Catalysis, 485, 110823.

This study investigated ammonia decomposition using alumina-supported mono- and bimetallic Co and Fe catalysts in a microwave reactor. The catalysts demonstrated high performance within the microwave system, reaching complete conversion at 400°C, but exhibited minimal activity in a conventional reactor. Microwave irradiation led to the formation of cobalt and iron carbides within the structures of the monometallic cobalt and iron catalysts. Prolonged microwave exposure further promoted carbide formation, enabling stable conversion during continuous flow experiments. Alumina-supported monometallic cobalt catalysts produced higher yields than monometallic iron catalysts, while bimetallic catalysts displayed superior activity, particularly at temperatures below 400°C.

Acknowledgments

We would like to thank our valuable professors Prof. Dr. H. Canan Cabbar, Prof. Dr. İrfan Ar, Prof. Dr. Çiğdem Güldür, Prof.Dr. Türkan Kopaç (Bülent Ecevit University), Prof. Dr. Suna Balcı, Assoc. Prof. Dr. Dolunay Eslek Koyuncu, Prof. Dr. Levent Değirmenci (Bilecik Şeyh Edebali University), Assoc. Prof. Dr. Veli Şimşek (Bilecik Şeyh Edebali University) Dr. Gamze Gündüz Meriç (Bilecik Şeyh Edebali University), Res. Asst. Rukan Can Seyfeli (19 Mayıs University), Res. Asst. Koray Kaysi (Eskişehir Technical University), Dr. Gökhan Ölmez and Assoc. Prof. Dr. Ahmet Pekediz (Canada) for their contributions to the CREG.

Recent Selected Papers in our Catalysis Community

In recent months, there have been exciting research studies in catalysis research in Turkey. Here are the short summaries:

Transition metal nitrides

Kizilkaya, A. C., Martínez-Monje, M. E., & Prieto, G. (2024). Synthesis of acetonitrile from NH3/syngas mixtures on molybdenum nitride: Insights into the reaction mechanism. Catalysis Today, 442, 114947.

Transition metal nitrides, particularly Mo2N, are promising catalysts for C-C and C-N coupling reactions, crucial for synthesizing nitrogenated chemicals from unconventional carbon resources. Experimental and computational studies show that a MoO3 catalyst precursor undergoes nitridation to form the active Mo2N catalyst, facilitating hydrogen-assisted CO dissociation and promoting C-N coupling with low energy barriers. The research highlights HCN as a key intermediate in acetonitrile formation, with surface oxygen playing a significant role in reaction kinetics, suggesting that enhancing HCN dissociation is critical for improving Mo2N catalyst performance.

Machine Learning

Tabriz, Z. H., Taheri, M. H., Khani, L., Çağlar, B., & Mohammadpourfard, M. (2024). Enhancing a bio-waste driven polygeneration system through artificial neural networks and multi-objective genetic algorithm: Assessment and optimization. International Journal of Hydrogen Energy, 58, 1486-1503.

This paper investigates the feasibility of using municipal sewage sludge as an energy source in a polygeneration system, which can simultaneously manage sludge disposal and produce renewable hydrogen. Through 4E (energy, exergy, exergoeconomic, and environmental) analyses and parametric studies, the system's performance is optimized using a genetic algorithm to balance exergy efficiency and cost. The results show that the gasifier has the highest exergy destruction rate, with an optimal exergy efficiency of 38.26%, a hydrogen production rate of 1692 kg/h, and a cost-effective hydrogen price of $1.49/kg.

Lanthanide Doped Ceria

Gürkaynak Altınçekiç, T., Güçtaş Gürel, D., Sarıboğa, V., Öksüzömer, M. F., & Arabacı, A. (2024). Synthesis and characterization of (Gd, Nd) co-doped ceramic materials (Gd0. 1NdxCe0. 9-xO2-δ x= 0.05, 0.10, 0.15) via polyol method using different hydrolysis ratios. Ionics, 1-10.

Gd0.1NdxCe0.9-xO2-δ x = 0.05, 0.10, 0.15 co-doped electrolytes were synthesized using the polyol process with varying metal concentrations and hydrolysis ratios. X-ray diffraction (XRD) analysis confirmed the purity and crystallographic properties while scanning electron microscopy (SEM) revealed uniform morphologies with grain sizes of 1–3 µm. Electrochemical impedance spectroscopy showed that the GNDC5-10 sample had the highest ionic conductivity of 4.86×10−2 S/cm, a relative density of 92.7%, and the lowest activation energy of 0.645 eV.

Transition metal complexes

Ulu, Ö. D., Serin, S., Özdemir, N., & Özdemir, İ. (2025). Synthesis, crystal structure, and DFT studies of NHC mediated Pd-PEPPSI complex: Application for Suzuki reaction. Journal of Molecular Structure, 1320, 139479.

A novel Pd-PEPPSI (pyridine-enhanced precatalyst preparation, stabilization, and initiation) complex was synthesized and characterized through spectroscopic and crystallographic techniques, with further structural and electronic analysis conducted using DFT calculations. This complex demonstrated high catalytic efficiency in the Suzuki–Miyaura coupling of aryl chlorides with phenylboronic acid, producing biaryl derivatives with yields ranging from good to excellent. The reactions proceeded under mild, aerobic conditions with minimal catalyst loading, utilizing an environmentally friendly water-based solvent system.

Nawaz, Z., Gürbüz, N., Zafar, M. N., Tahir, M. N., Özdemir, İ., & Trovitch, R. J. (2024). Design of efficient benzimidazole-derived N-heterocyclic carbene Ag (I) catalysts for aldehyde–amine–alkyne coupling. Journal of Molecular Structure, 1318, 139239.

A mild catalytic method for the A3-coupling of aldehydes, amines, and alkynes was developed using BNHC silver(I) catalysts, facilitating the selective synthesis of propargyl amines. Structural analysis of BNHC Ag(I) halide complexes was conducted using NMR, FT-IR spectroscopy, and X-ray diffraction. This environmentally benign approach produced propargyl amines with yields of up to 95%, generating water as the sole byproduct.

Tuncer, H., Kılınçarslan, R., Karci, H., Dündar, M., Özdemir, İ., Koç, A., ... & Çetinkaya, B. (2024). Synthesis, electrochemical, biological, and catalytical studies of half-sandwich Ru (II)-NSHC complexes bearing benzothiazol-2-ylidene. Journal of Molecular Structure, 1318, 139424.

Half-sandwich ruthenium (II)-NSHC complexes were synthesized under mild conditions via in situ deprotonation of N-substituted benzothiazolium salts with Ag₂O and [(p-cymene)Cl₂Ru]₂. These complexes were characterized using spectroscopic techniques and X-ray crystallography and demonstrated catalytic activity in the transfer of hydrogenation of carbonyl compounds to secondary alcohols. Furthermore, structural variations within the Ru(II)-NSHC complexes influenced their anticancer, antifungal, and antimicrobial activities.

Ionic Resins

İlgen, O., & Baytaş, E. (2024). Kinetic and Parametric Studies on Oleic Acid Esterification Catalyzed by Purolite CT151. Chemical Engineering & Technology, e202400141.

This study investigated the esterification of oleic acid with methanol using a Purolite CT151 catalyst, with a primary focus on reaction parameters, kinetics, and mechanism. The optimal conditions, including a methanol-to-oleic acid molar ratio of 12:1, a 20% catalyst concentration, a reaction time of 7 hours, and a reaction temperature of 67 °C, resulted in an 84% conversion of oleic acid. Surface characterization using FTIR and SEM analyses confirmed an Eley–Rideal reaction mechanism, in which methanol adsorbs onto the catalyst surface and subsequently reacts with oleic acid prior to water desorption.

Steam Reforming

Öztürk, A. P., Oğuz, M., Tüter, M., Bayazit, Ş. S., & Özkara-Aydınoğlu, Ş. (2024). A comprehensive thermodynamic analysis of hydrogen and synthesis gas production from steam reforming of propionic acid: Effect of O2 addition and CaO as CO2 sorbent. International Journal of Hydrogen Energy, 81, 1374-1384.

This study analyzed the production of hydrogen and synthesis gas via steam reforming of propionic acid, with a focus on the steam-to-propionic acid ratio, reaction temperature, O2 addition, and the use of CaO as a CO₂ sorbent. Higher steam ratios were found to increase H₂ and CO₂ yields while reducing coke formation by promoting the water-gas shift (WGS) reaction over the Boudouard reaction. Additionally, the presence of CaO further improved H₂ yield and process efficiency, achieving a 100% H2 yield with minimal byproducts at 600 °C under sorption-enhanced steam reforming conditions.

Applied Catalysis Seminar

The "Applied Catalysis Seminar" was organized by the Department of Chemical Engineering at Ondokuz Mayis University on October 17-18, 2024, with the support of TUBITAK 2237. This event marks the first major organization prepared by our academic staff. The seminar aimed to provide a comprehensive learning experience for graduate students and early-career researchers. Participants received insights into fundamental concepts, design, optimization, and characterization of catalysts from recognized and leading faculty members, while also understanding the significance and scope of current examples.

The theoretical training sessions of the seminar took place in the Conference Hall of the OMTEL Hotel at Ondokuz Mayis University. The first day began with Prof. Dr. Fatma Çiğdem GÜLDÜR's lecture on "Selection and Preparation Techniques for Catalysts in Reactions." This was followed by Prof. Dr. Ramazan YILDIRIM addressing "Future Trends in Catalysis and Applications of Artificial Intelligence in Catalysis." Participants then engaged in practical sessions with Dr. Gülce ÇAKMAN on "Catalyst Synthesis Using Microwave Method" and Rukan Can SEYFELI on "Catalyst Synthesis Using the Impregnation Method," gaining familiarity with catalyst synthesis methods and hands-on experience in a laboratory setting.

On the second day, theoretical training continued with Prof. Dr. Deniz ÜNER's lecture on "Fundamental Principles of Catalysts and Catalyst Analysis with Spectroscopic Methods." Following this, Prof. Dr. Alper UZUN covered "Catalyst Design, Optimization, and Performance Evaluation." Additionally, under the supervision of Asst. Prof. Elif CAN ÖZCAN and Assoc. Prof. Gediz UGUZ, the XRD, TGA, and SEM-EDS methods were taught interactively to students at the OMÜ Black Sea Advanced Technology Research and Application Center (KITAM) laboratories.

While the event was scientifically productive, guests had the opportunity to explore Samsun and enjoy local cuisine. For accommodation, OMTEL Hotel was chosen for its peaceful atmosphere, offering stunning sea views and a green environment.

The seminar provided participants with interactive sessions and opportunities for knowledge exchange with experts, enhancing their understanding of catalyst technologies. We plan to continue organizing such events. You can stay updated on our latest activities by following us on our social media accounts (https://www.instagram.com/kimyamuhendisligiomu/, linkedin.com/in/omü-kimya-mühendisligi-bölümü-3b18892aa). We would like to thank everyone involved in this event, especially the coordinator Assoc. Prof. Dr. Gediz UGUZ, the organizing team, educators, and all participants.

Upcoming Catalysis Events

10th National Catalysis Conference (NCC10), coordinated by the Catalysis Society will be held in collaboration with Cumhuriyet University in Sivas from June 26 to 28, 2025. Prof. Ayten Ateş is the chair of the organizing committee. Details will be announced in subsequent bulletins.

16th European Congress on Catalysis (EuropaCat 2025) (https://www.ntnu.edu/europacat2025), coordinated by the European Federation of Catalysis Societies (EFCATS) will be held in collaboration with the Nordic Catalysis Societies in Trondheim, Norway from August 31, 2025 to September 5, 2025.

36th National Chemistry Congress (UKK2025) (https://kimya2025.com/) will be held in Van between September 1-4, 2025, under the coordination of the Turkish Chemistry Association, in cooperation with Van Yüzüncü Yıl University.

16th National Chemical Engineering Congress (UKMK2025) will be held in Bolu between September 9-12, 2025, under the coordination of İzzet Baysal University.

Save the dates to your calendars!

Don't miss out! Register now for these events and be part of the catalysis community.

In my opinion, the world we live in has become increasingly beautiful and has brought more joy to life, due to its constant motion and the ongoing search for a better world.

Quoted from “In Search of a Better World” book by Karl R. Popper

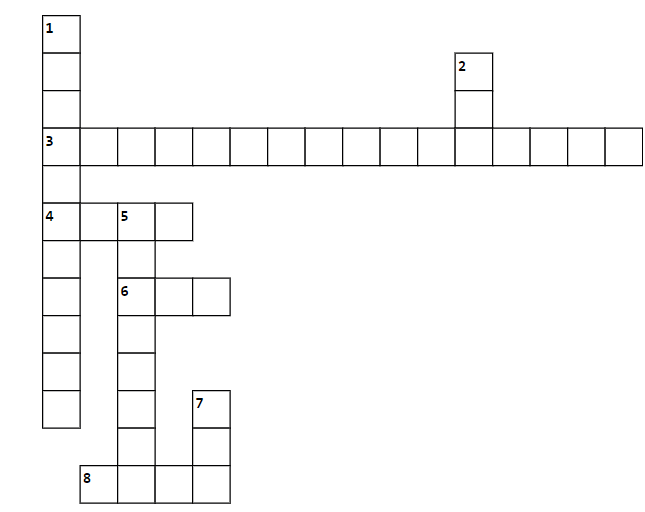

Crossword Puzzle